Increased efficiency at the Maggi factory: Precise measurements reduce heat loss

Making invisible energy losses visible: Katronic shows how the Maggi factory in Singen is reducing costs and increasing efficiency

The food company Nestlé operates a Maggi factory in Singen that is over 125 years old. This is one of Nestlé's largest production sites in Germany: every year, almost 40 million bottles of Maggi seasoning and over 30 million cans of ravioli leave the traditional halls. In order to make production CO₂-neutral in the long term, a precise analysis of heat requirements is a key step – especially with regard to future electrification using heat pumps.

The infrastructure there comprises 40 buildings with a variety of different media: from steam to hot and cold water to condensate. For a realistic assessment, a total of 16 measuring points had to be taken into account – a challenge given the large number of aggregate states and lines in the system.

We at Katronic were happy to take on this challenge. Due to their ability to measure heat quantities, the KATflow 150 device types, which are actually intended for permanent installation, and the portable KATflow 230 were ideal as measuring devices. One measuring point was also covered by a KATflow 200 device, as temperature measurement was not necessary at this point.

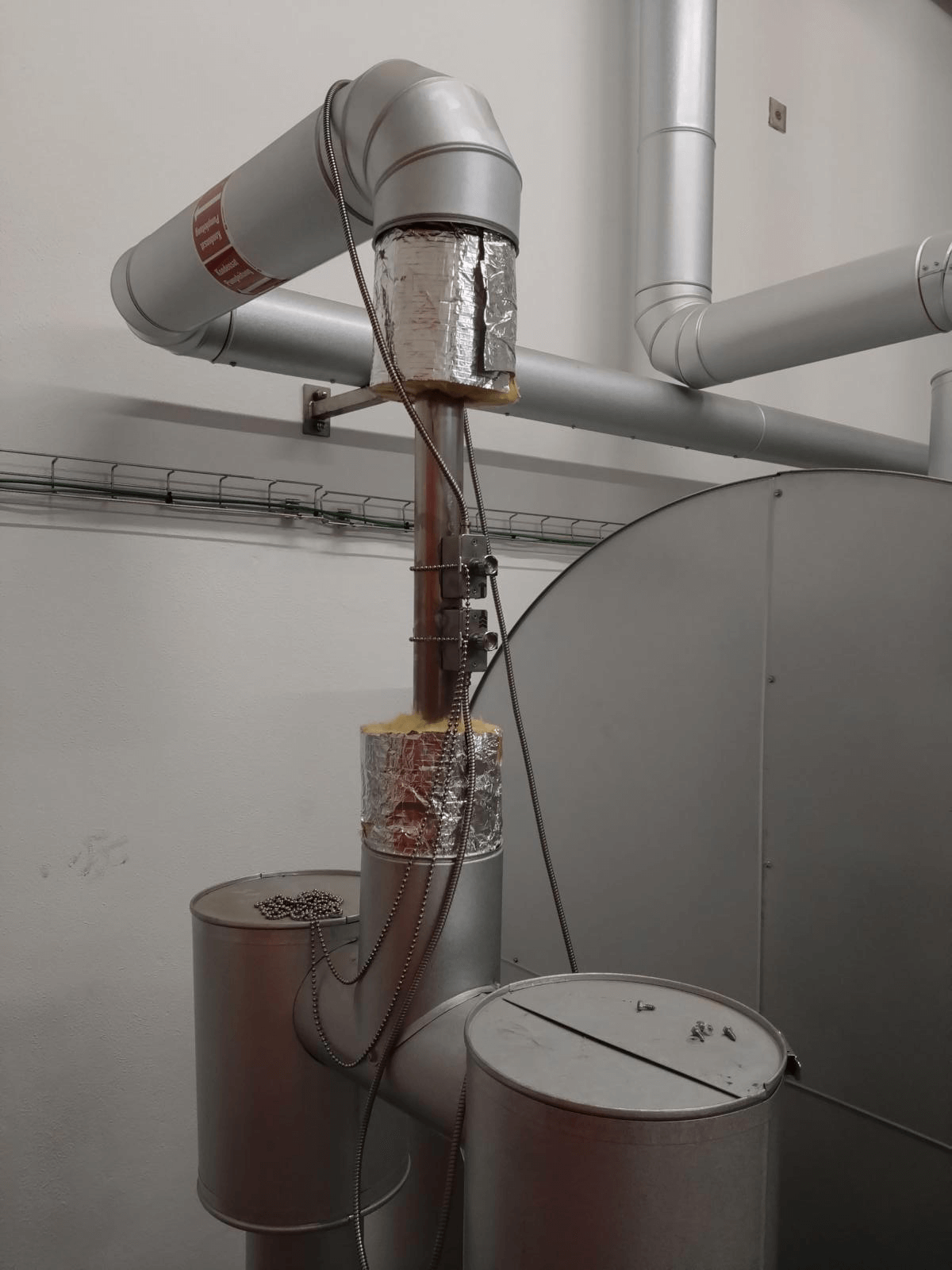

Water volume measurements were carried out at twelve points in the system, mainly for hot water. Steam measurements were also to be carried out at five points. A test measurement was first carried out to determine the feasibility of this. This produced isolated measured values, but the measurement conditions were not sufficient to achieve clear results due to condensation on the inside of the pipes and irregular flow velocities. For this reason, an alternative water flow measurement of the condensate was carried out at four points in the system.

Among other things, the measurements revealed excessive heat losses in a pipe supplying hot water to the system. These losses were eliminated by specifically relocating the pipe, with measurable success: the plant now saves around €10 000 in energy costs annually.

The investment in measurement technology will therefore pay for itself within a short period of time and not only delivers financial benefits, but also contributes to reducing CO₂ emissions at the site.

Overview

Overview Oil and Gas

Oil and Gas Manufacturing and Process

Manufacturing and Process Food and Drink

Food and Drink Building Services

Building Services Aircraft and Aerospace

Aircraft and Aerospace Chemical and Petrochemical

Chemical and Petrochemical Power Generation

Power Generation Marine and Shipbuilding

Marine and Shipbuilding Water and Wastewater

Water and Wastewater Pharmaceutical

Pharmaceutical Flowmeter Hire and Rental

Flowmeter Hire and Rental Measurement Service

Measurement Service Training

Training Commissioning

Commissioning Special Solutions

Special Solutions