How does liquid flow measurement work?

We develop and manufacture portable and fixed installation clamp-on flowmeters for liquids, which maintain high quality production standards and performance characteristics. We believe that the measurement of flow should be quick, easy and straightforward. We have therefore equipped every KATflow clamp-on flowmeter with an intuitive menu, instrument Setup Wizard and the unique Audible Sensor Positioning Assistant to make our flowmeters the easiest to operate and install available.

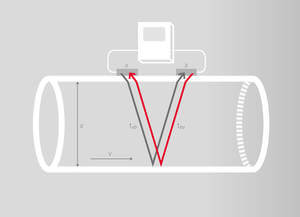

Katronic ultrasonic flowmeters can measure on pipes of all standard materials over a large diameter range and are suitable for process liquids from pure water to chemicals and effluents. The instruments measure over a range of 0.01… 25 m/s and a repeatability of 0.15 %.

To ensure the long term performance and reliability of our products, KATflow instruments are supplied with stainless steel transducers as standard on all models and housings designed to withstand even the most harsh environmental conditions.

Overview

Overview Oil and Gas

Oil and Gas Manufacturing and Process

Manufacturing and Process Food and Drink

Food and Drink Building Services

Building Services Aircraft and Aerospace

Aircraft and Aerospace Chemical and Petrochemical

Chemical and Petrochemical Power Generation

Power Generation Marine and Shipbuilding

Marine and Shipbuilding Water and Wastewater

Water and Wastewater Pharmaceutical

Pharmaceutical Flowmeter Hire and Rental

Flowmeter Hire and Rental Measurement Service

Measurement Service Training

Training Commissioning

Commissioning Special Solutions

Special Solutions