Wireless Data Show the Future for Katronic Flowmeters

Katronic Technologies are pleased to announce that their KATflow clamp-on ultrasonic flowmeters are now available with a variety of new output communication options to cover a range of different applications

The need for better information is driving the advance of smart metering instruments. Over time, there has been a steady increase in customers requesting communication able to provide simultaneous multiple variables including diagnostic data. During this process, it has become apparent that trying to take a ‘one language fits all’ approach to this will not work. Each industrial sector use systems with their own preferred communication methods, and therefore standardisation is not an option from a manufacturer’s perspective. In order to meet the needs of engineers it is important for Katronic to provide a solution to suit the individual application or system to which our meters are connected.

The process of adding greater flexibility into the KATflow meters has been ongoing for some time and took a leap forward in 2016 with the installation of our first flowmeter with wireless data transmission. A company approached us to provide an instrument with remote data acquisition as part of large evaluation project they were working on at General Motors. During the initial discussions, the customer specified that they required an instrument with a hard-wired Ethernet connection that would transmit data via the end user’s own network.

In our efforts to support the customer as fully as possible we were very keen to make sure that personnel from Katronic were available during the commissioning of the new device. Although we had thoroughly tested the meter before delivery to site, we wanted to ensure that the installation and connection process would be as smooth as possible. At this stage, one of the Katronic engineers noticed that whilst the data appeared locally the remote server was not seeing it. Following some detective work, the Katronic engineers attributed this unexpected issue to the end-customer’s network permissions. After an assessment of the situation and some feedback from the customer, we decided that a wireless solution would be of the greatest benefit.

To support the new suggestion we firstly adapted the KATflow 150 to accommodate an antenna, something that was quite simple owing to its flexible modular design. We then had two weeks to finalise and test the new wireless communication and supply the solution to the customer. The final installation stage of the process went very smoothly as within minutes the flowmeter was measuring; communicating over 3G. The customer could exactly follow what was happening with the flowmeter with the remote software updating every 30 seconds.

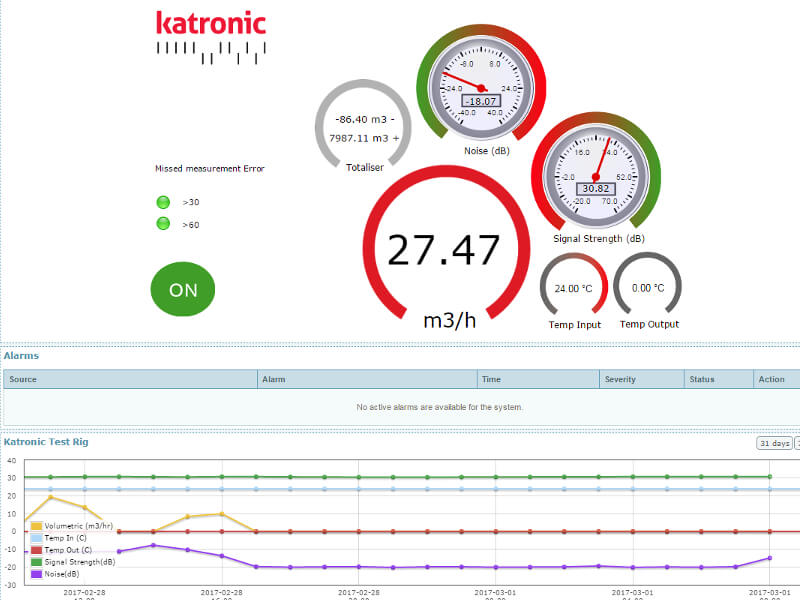

In addition to simply having flow data, the flowmeter is also fitted with two PT100 temperature inputs providing live heat quantity data in kW and totalised value in kWh. The remote software (see picture) also provides the user with feedback on the operating condition of the flowmeter as the instrument diagnostic data is also available online. The KATflow 150 generates information on signal strength, and condition as well as other useful variables indicative of meter performance.

Overview

Overview Oil and Gas

Oil and Gas Manufacturing and Process

Manufacturing and Process Food and Drink

Food and Drink Building Services

Building Services Aircraft and Aerospace

Aircraft and Aerospace Chemical and Petrochemical

Chemical and Petrochemical Power Generation

Power Generation Marine and Shipbuilding

Marine and Shipbuilding Water and Wastewater

Water and Wastewater Pharmaceutical

Pharmaceutical Flowmeter Hire and Rental

Flowmeter Hire and Rental Measurement Service

Measurement Service Training

Training Commissioning

Commissioning Special Solutions

Special Solutions