Keeping the Sludge Flowing

Supporting our supply chain partners through lockdown

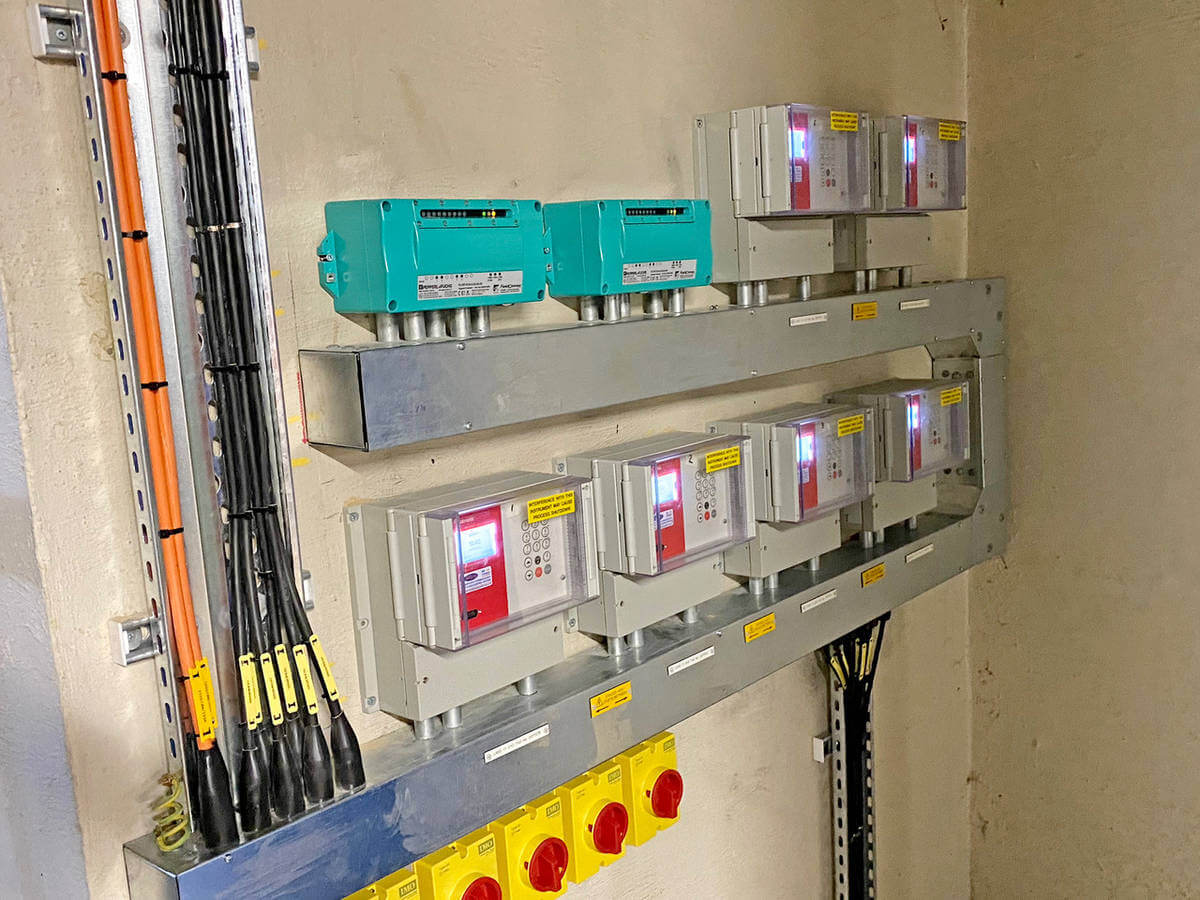

Critical work continues on wastewater treatment works up and down the country. Katronic man Matt Bird visited site to support work being done by Z-Tech at a very large STW in southern England to commission six KATflow 150 non-invasive clamp-on flowmeters, supplied through ABB. The project measures RAS/SAS (raw activated sludge/surplus activated sludge) flow through sixteen lines of grey cast-iron pipes and features Profibus PA, the first clamp-on flowmeters to do so in the UK. Needless to say, all distancing and safe working practice protocols were followed on site and Matt visited site as an approved 'critical supplier' for the project.

Monitoring RAS and SAS is important in properly balancing sludge processes, so an accurate, repeatable measurement of flow is key. The sixteen lines being measured are grey cast iron, installed between the 1930's and 1950's, with diameters from 80 to 440 mm. The measurement was made more difficult by the presence of a build-up of sludge on the inside of the pipes, so KATflow 210 and KATflow 230 had previously been installed on a 24-hour process logging trial to prove the reliability of the measurement, leading to the order for permanently installed KATflow 150 units.

For the main installation, the sensors are positioned approximately 50 m from the control units. Katronic's Audible Sensor Positioning Assistant helps when it isn't possible to see the controller but, obviously, it has to be within earshot, so Matt Bird made use of Katronic's small Remote Positioning Assistant, which allows a hand-held KATflow 200 to be used to set the sensors up before connecting them to the main controller.

Matt also installed Profibus PA interface boards into each of the KATflow 150's, allowing them to connect to the site supervisory control system. We believe that this is the first Profibus PA installation in the UK for non-invasive, clamp-on flowmeters.

Overview

Overview Oil and Gas

Oil and Gas Manufacturing and Process

Manufacturing and Process Food and Drink

Food and Drink Building Services

Building Services Aircraft and Aerospace

Aircraft and Aerospace Chemical and Petrochemical

Chemical and Petrochemical Power Generation

Power Generation Marine and Shipbuilding

Marine and Shipbuilding Water and Wastewater

Water and Wastewater Pharmaceutical

Pharmaceutical Flowmeter Hire and Rental

Flowmeter Hire and Rental Measurement Service

Measurement Service Training

Training Commissioning

Commissioning Special Solutions

Special Solutions